Jun. 06.2023

Kito Hoists Reinforce Fishing Fleet

We visited a shipbuilder in Ishinomaki, Miyagi Prefecture that produces aluminum boats for commercial fishing. In March, twelve years after the Great East Japan Earthquake hit the region, we met President Takashi Kakinuma of Shoninbori Tekkosho and asked him to talk about purse-seine fishing and what’s special about the boats they build for the industry.

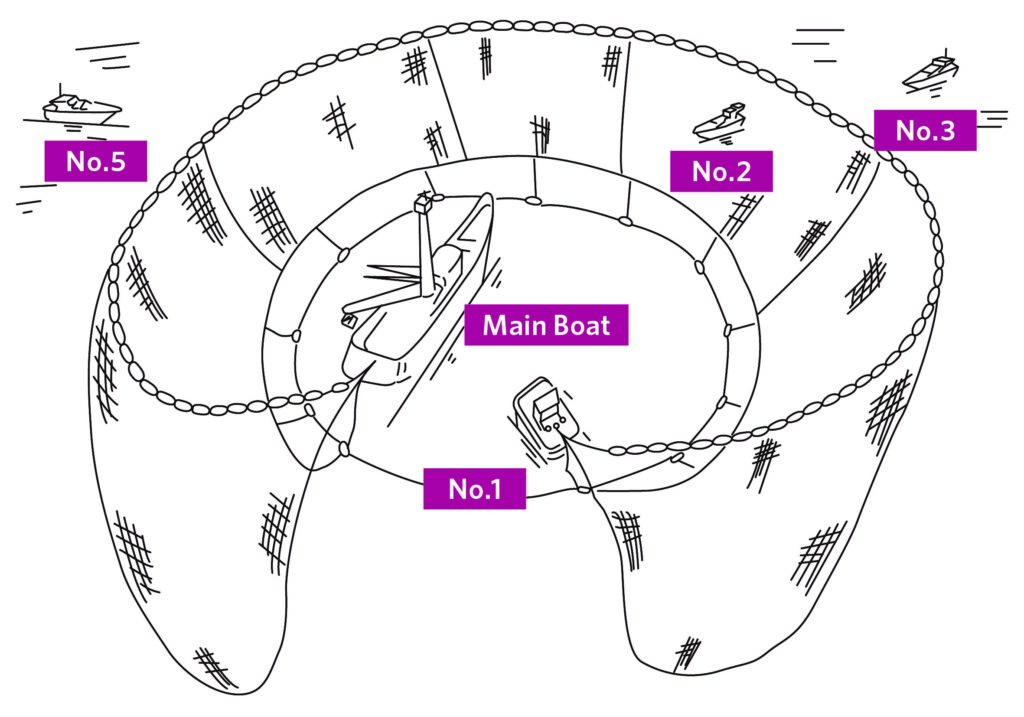

In purse-seine fishing a main boat goes to sea with three or four smaller boats aboard. The largest of those, No. 1, rides on the aft deck, and once the crew locates a school of bonito, they crane it off to the sea surface with one end of the net attached. The main boat then navigates a large circle, enclosing the fish in the net, which has a wire along the edge to close the bottom.

Shoninbori Tekkosho builds these smaller boats, which must be light, rust-resistant and sturdy. The ribs and hull plates are cut from a single aluminum sheet, mostly by machine and some by hand. Welding aluminum, which is much softer than steel, is particularly difficult, requiring advanced techniques and experience. The ribbed skeleton is welded to the keel, the hull plates attached, and with engine and cockpit installed the boat is complete. It’s a sturdy piece of art made by skilled craftspeople.

In the shipyard separate teams of four to six people build the hulls and superstructures and install engines and other equipment, each team working through to completion of each boat order, which takes about five months. The company usually delivers packages of four boats, numbered 1, 2, 3 and 5 — skipping 4, considered an unlucky number in Japan because it sounds the same as the word for death — to customers spread nationwide, Kyushu to Hokkaido.

On the twelfth anniversary of the earthquake both Shoninbori Tekkosho and the people of Ishinomaki are doing well, overcoming the damage they suffered in the tsunami following the quake.

President Takashi Kakinuma (right)