Sep. 15.2021

Automation Meets Traditional Craftsmanship—Kito Lever Hoist

The lever hoist is like our middle name at Kito, an essential tool for holding, fastening and

positioning loads. Employed in every industry, these hoists are especially powerful where work

conditions are tough, as on construction sites, on transports and in shipyards. They are small and light, but extremely durable. How does Kito make these signature products?

We start with an automated process of forming and punching coiled steel sheet into hoist frames and cases. In the photo you can see the high-frequency heat-processing line used to strengthen these frames. The line requires minimal energy for cooling, reducing energy demand.

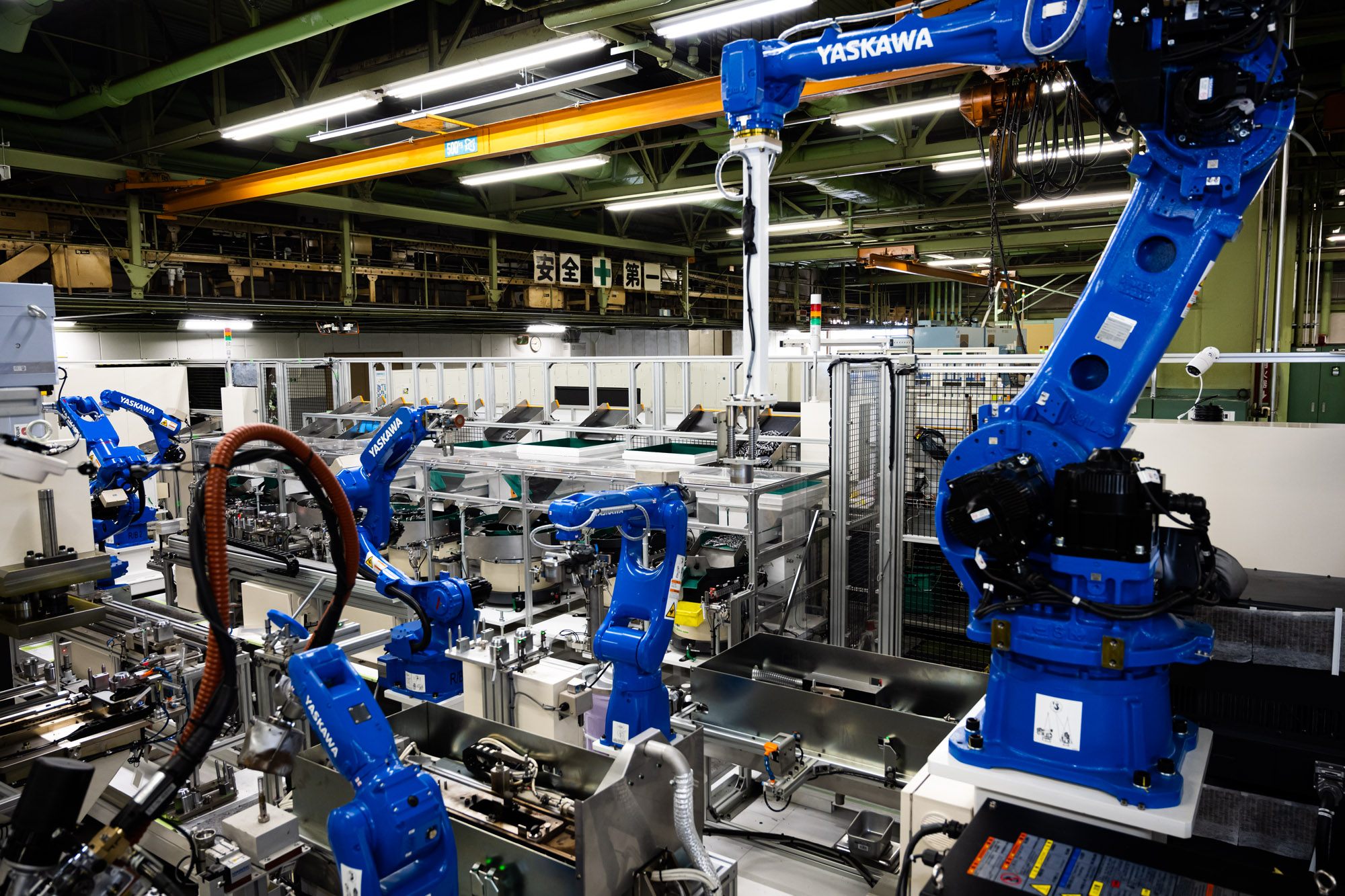

On the lever-hoist part-processing line, blue robots line up neatly for efficient work. Seven robots work together with superb coordination, handling four processes, including part-mounting and welding. Once the materials are fed in, all processes are handled automatically, even outside normal work hours, to flexibly handle fluctuations in production demand.

On the line for final assembly and inspection, experienced craftsmen take charge. Finished products

come off the line one after another in the blink of an eye, the result of excellent teamwork. Each product is manually inspected to guarantee quality. Kito people work side-by-side with robots on the line, each fulfilling their specific assignments to complete our famed lever hoists.