Sep. 01.2020

The Unknown World of Chain, Part2 – The Big Decision to Automate

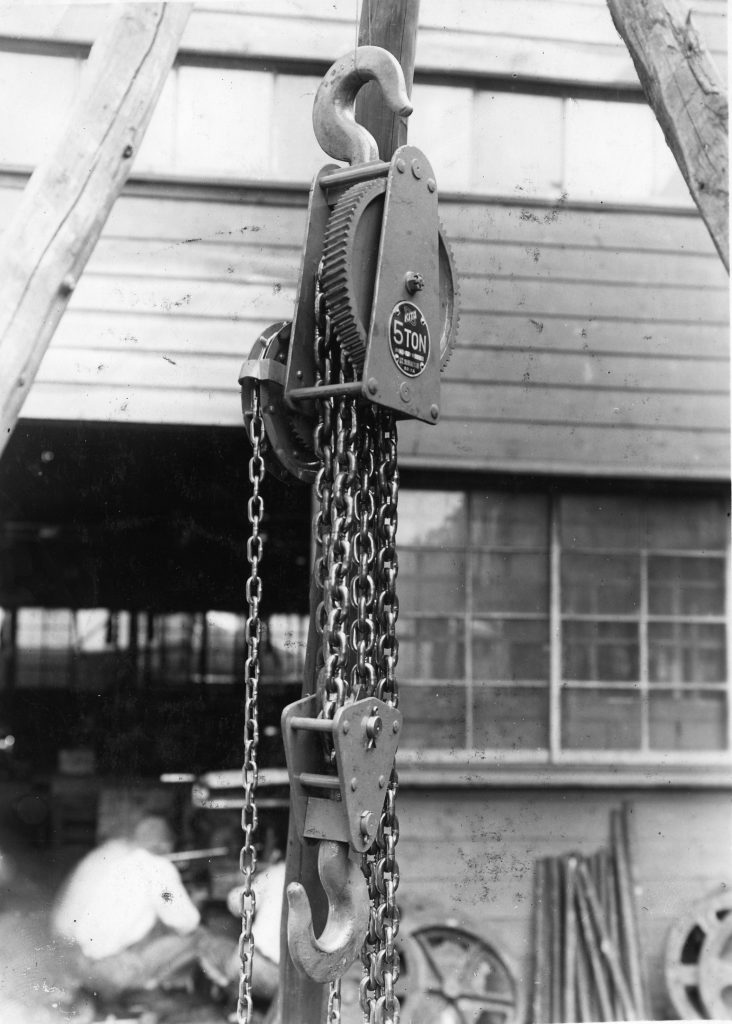

The history of the chain hoist is long. At Kito it starts in 1937, five years after the company’s founding, when we successfully developed a revolutionary steel chain hoist with three advantages: it was smaller, lighter and stronger.

In those days we outsourced chain for the hoists. Understanding that the life of a chain hoist depends on the quality of its chain, within a couple of years we decided to produce it in-house. Bending, welding and other important processes began with hand work by our craftspeople. Success with that soon led to a sudden surge in demand, necessitating changes in our production system that depended heavily on experienced workers, resulting in a major shift to more rational automation.

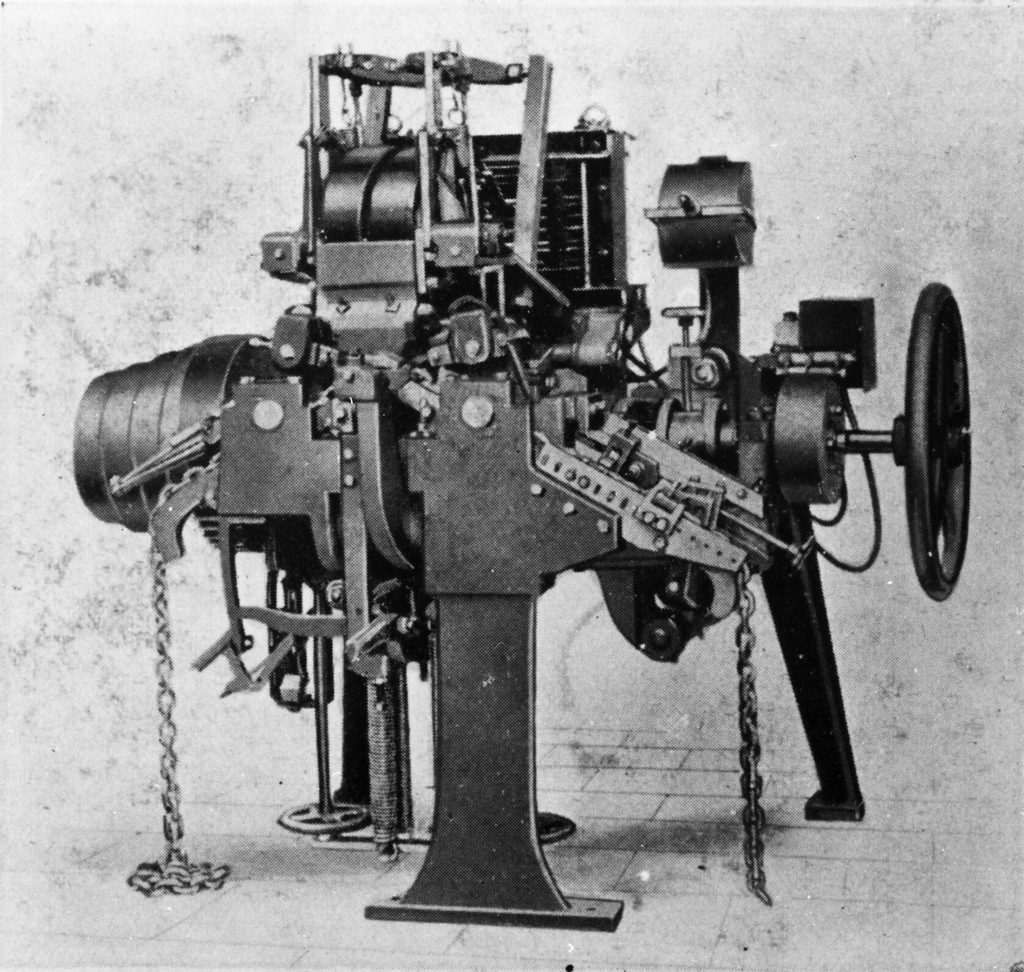

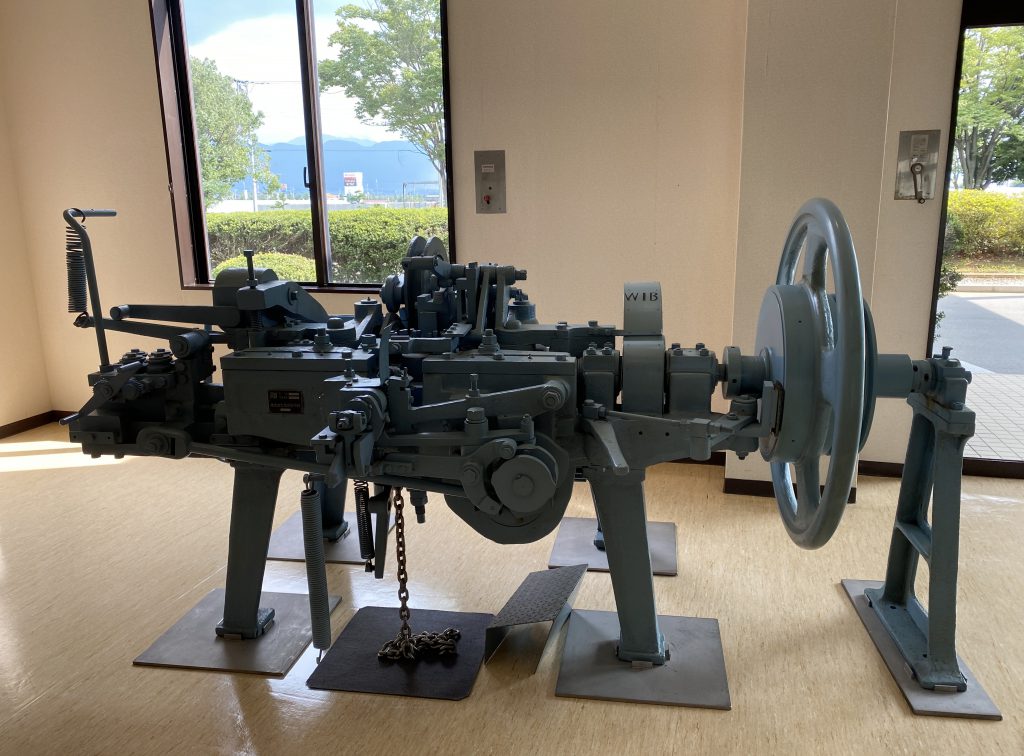

In 1939 Kito made the important decision to invest in bending and welding machines for chain production, imported from Germany, ahead of the rest of the industry in Japan. Symbolizing the move to automated chain production, those machines are still displayed at our Yamanashi main plant, illustrating our history of manufacturing innovation.

What impelled the company to shift to in-house production of chain was our founder’s strong conviction that chain quality is essential to the safety and endurance of Kito products. This understanding has passed down to every Kito employee as a firm, continuing commitment.

In Part 3 we’ll follow the postwar development of Kito chain.